- Reservoir Monitoring

- Production Optimization

- Fiber Optics

- Services

- About

- News

- Resources

- Careers

- Contact

Reservoir Monitoring

Production Optimization

Fiber Optics

Services

About

News

Resources

Careers

Contact

It’s a hot topic in oil & gas these days, but how exactly does DAS work, and what practical applications does it offer?

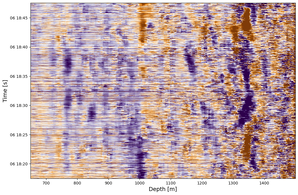

Distributed Acoustic Sensing (DAS) is a technology that uses fiber optic cables to detect and analyze acoustic vibrations along pipelines, transmission lines, facility perimeters, and within wellbores among other utilization methods.

So how does it actually work for oilwells? First, a fiber optic cable is installed downhole. The cable acts as a sensor, detecting vibrations or sound waves generated by “events” along the length of the cable. An interrogator unit sends laser pulses through the fiber, and measures the backscattered light (which is affected by the acoustic vibrations). Finally, the data is analyzed to identify the location and characteristics of the detected “events.”

DAS can monitor downhole conditions including production flow, fluid phase, completion parameters, fracturing, casing integrity, and provides valuable data for optimizing production and identifying potential problems. DAS is particularly effective in determining flow conformance and detecting leaks (even tiny ones) because it can sense subtle vibrations caused by dynamic fluids. Operating DAS and DTS (Distributed Temperature Sensing) simultaneously allows for correlated data that provides significant enhancement and validation of the data.

Petrospec primarily offers integrated DAS and DTS systems as well survey service for well integrity by acquiring acoustic logs of the wellbore. With DAS signal processing and highly-specialized interpretation, we coordinate with industry leading DAS technology partners for more complex or demanding applications, like flow profiling. In either case, we manage the entire process for installing a suitable downhole optical sensor system, surface tie-in, data acquisition and report generation.

Features of DAS:

Advantages of DAS:

Contact Petrospec today if you have any questions or would like to learn more about their DAS offering.

About Petrospec Engineering

Established in 1997, Petrospec is proud to be a leading provider of turn-key reservoir monitoring systems for oil and gas operators. We strive to improve efficiency, meet high safety standards, and provide equipment and software for harsh environments. Our Edmonton-based company is a global innovator in downhole instrumentation, production optimization, and the accurate measurement of temperature, pressure, acoustics, and flow.

Back to news