- Reservoir Monitoring

- Production Optimization

- Fiber Optics

- Services

- About

- News

- Resources

- Careers

- Contact

Reservoir Monitoring

Production Optimization

Fiber Optics

Services

About

News

Resources

Careers

Contact

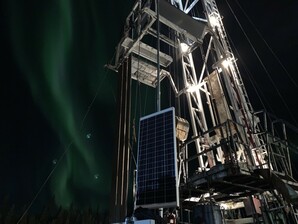

The numbers add up to a busy winter for Petrospec and their clients—the busiest observation well season in years.

Petrospec worked closely with production engineers to optimize well completions based on successful historical data. “We talked extensively with our clients to find a design that works best for them and their particular needs,” shares Mick Chalifoux, account manager at Petrospec. “We’re really happy with our Q1 performance this year. We were fortunate to work with almost every major producer in Alberta,” said Chalifoux.

And even though it was a busy season, they were still able to answer the call when clients needed to fill a last-minute order—so what would normally equate to a 3 or 4-month lead time was delivered in 2 weeks. Meeting those tight turn-around times, while maintaining quality control, is clearly something Petrospec strives for on every job. Perhaps also noteworthy, each well comes with an engineered document package to further support clients.

These product lines top Petrospec’s list of installs this winter:

Dual Vibrating Wire (VW) Pressure and Temperature Gauge: Used to provide continuous pressure and temperature monitoring at a desired well depth, the Dual VW pressure sensor provides excellent long-term accuracy, stability of readings, and reliability under demanding conditions such as SAGD and other thermal applications.

Standard construction consists of high-temp stainless steel alloys with connections made using a robust magnesium oxide (MgO) mineral insulated (MI) cable for maximum strength and temperature rating. The combination MI cable has 2 independent circuits with each circuit terminating inside the gauge housing, which is responsible for independent pressure and temperature readings.

Petrospec’s experience with MI cables over the past 8 years has been very successful with several thousand MI cable installations. Petrospec’s MI thermocouple cables have excellent mechanical strength, superior corrosion and scaling resistance, and are resistant to stresses like bending, twisting, or flattening.

Temp-Line™: As Petrospec’s newest in-house development, these multi-point sensor cables can be configured with up to 60 thermocouple points inside ½” tubing. With 100% customizable point locations, this product offers a smaller footprint at an even smaller price point compared to traditional MI cable.

In preparation for their busiest season, Petrospec onboarded several new staff including 3 co-op students from the University of Alberta. Time spent on training new staff was also increased, knowing the investment would pay off in Q1.

When hard-working people and fine-tuned products come together, all parties achieve success. Petrospec aims to keep the momentum going for the remainder of this year, and into their next winter program.

About Petrospec Engineering

Established in 1997, Petrospec is proud to be a leading provider of turn-key reservoir monitoring systems for oil and gas operators. We strive to improve efficiency, meet high safety standards, and provide equipment and software for harsh environments. Our Edmonton-based company is a global innovator in downhole instrumentation, production optimization, and the accurate measurement of temperature, pressure, acoustics, and flow.

Back to news